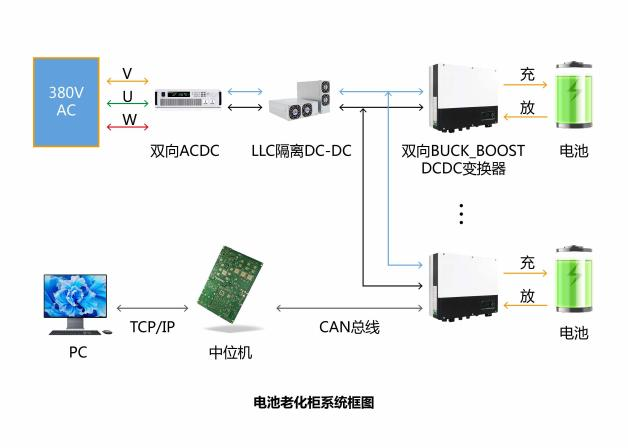

1、 Equipment principle and composition

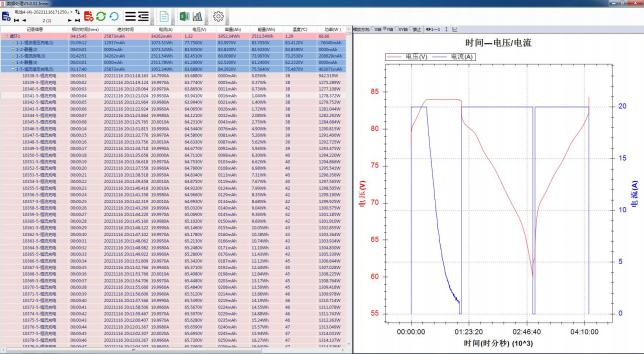

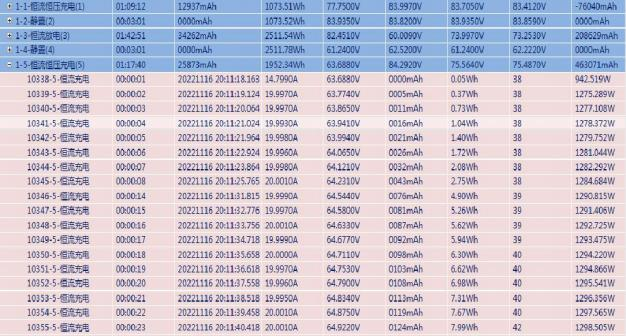

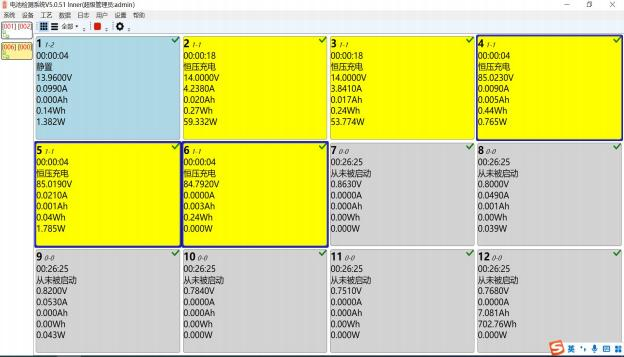

1.1 Upper computer: The upper computer software is the main human-computer interaction tool, and the functions of starting, stopping, pausing, and connecting the equipment can be implemented through the upper computer; The data of battery aging is mainly collected and processed by the upper computer, and the test results required by customers are output.

1.2 Median machine: The median machine is the equipment control management software, and the capacity, power, and other parameters of battery testing are calculated by the median machine.

1.3 Bidirectional ACDC+LLC isolated DCDC: During charging, this functional module takes power from the grid, regulates it through bidirectional DCDC, and then charges the battery; During discharge, this functional module feeds back the energy transmitted from bidirectional DCDC to the grid.

1.4 Bidirectional DCDC (Buck/Boost): This functional module is a non isolated DCDC, which outputs the current and voltage values required for battery charging and discharging, including constant current charging, constant voltage charging, and constant current discharging.

2、Scope of Application

An integrated charging and discharging cycle testing system for lithium battery packs used in electric tools, solar energy storage, torque scooters, scooters, electric bicycles, electric motorcycles, household energy storage, etc.

3、 Equipment environmental requirements and technical parameters

3.1 Whole cabinet power supply: AC voltage 380V ± 10%, frequency: 50Hz ± 10%;

3.2 Environmental temperature: -10~45 ℃;

3.3 The environment is free from strong vibrations, corrosive gases, and flammable and explosive gases.

4、 Function Introduction

4.1 Charging and discharging function: It has constant current and constant voltage charging function and constant current discharging function, which can charge and discharge the battery and record the battery capacity;

4.2 Checking voltage protection: By charging and discharging the battery, check whether the charging and discharging protection of the battery are working;

4.3 Safety protection: anti reverse connection protection function, power down data protection, support for continuous testing, voltage upper and lower limit setting protection, and safe discharge current protection;

4.4 Adopt high-frequency isolation method to isolate the entire system from the power grid, ensuring safe and stable operation of the system;

The 4.5 bidirectional ACDC module adopts space vector modulation technology and digital control, which enables high voltage utilization and smaller current harmonic diversion;

4.6 Can achieve internal conversion of dual channel charging and discharging energy;

The 4.7DCDC module adopts advanced PID regulation technology and multiple protection mechanisms to ensure the stability of equipment operation;

4.8 Energy feedback (DC bus efficiency ≥ 93%): Energy feedback type, battery discharge energy can be fed back to the grid;

4.9 Seamless switching between constant current and constant voltage modes without any voltage or current surges. It can effectively prevent the battery from losing powder due to heat concentration caused by peak current;

4.10 Voltage and current are sampled using a four wire system, with high voltage sampling accuracy and good long-term stability;

4.11 Single channel has independent operation capability and supports multi-channel parallel output;

4.12 Supports battery barcode input, with traceable historical test data.